- Sherline rotary table deskcnc generator#

- Sherline rotary table deskcnc manual#

- Sherline rotary table deskcnc full#

- Sherline rotary table deskcnc code#

RTPC can also be output independent from a given machine kinematic configuration when using vectors. In addition, tool control center point RTPC output for cutting and rapid positioning improves machine movement, resulting in faster feed rates and higher surface quality when output using absolute values. This optimized point distribution also maintains the surface quality and smooth trajectories around sharp curves.

Sherline rotary table deskcnc code#

To accomplish this in 5-axis, ESPRIT optimizes linear and angular point distribution and the number of blocks of code to accommodate faster look-ahead processing in the CNC control. Machine-optimized, edit-free G-code produces shorter setup times and faster cycle times. This high-performance cycle uses a simple four-step workflow while providing extensive control over the cutting tool movements to support the unique requirements of a tremendous variety of applications. Unique to ESPRIT is the patented FreeForm 5-axis composite cycle, a combination of six different machining patterns and six tool orientation strategies for a total of 36 different toolpath types. Rdr online carcano or rolling blockĮach of these cycles has high-speed machining built in.

Sherline rotary table deskcnc full#

Use this powerful suite of cycles in full 5-axis, lock one axis for 4-axis applications like screws and blades, or lock two axes for maximum rigidity in heavy cuts.

Sherline rotary table deskcnc manual#

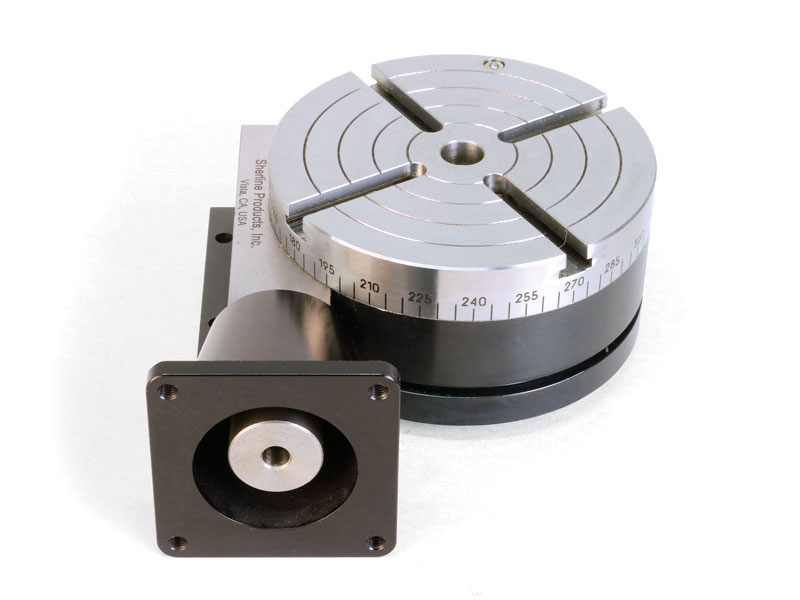

The key differences being the Sherline’s through motor manual handle, programability and the latter’s lower price due to being in kit form.For simultaneous 5-axis freeform machining, ESPRIT has nine families of rough and finish machining cycles for a wide variety of parts - from micromachining to heavy industry. It looks quite similar to the DivisionMaster product designed by Tony Jeffree which is available in kit form from the Model Engineers Digital Workshop. Another issue mentioned in the manual is that turning on and off the power might affect positioning so you may have to re-align work if it is machined over several sessions.

Sherline rotary table deskcnc generator#

The through motor handle seems like a good idea but a side effect of using it is mentioned in the manual which is that it can act like a generator and potentially damage the control box. There is a lot of supporting information on the sherline website and there is a strong following so there are plenty of other hobbiests and groups using the equipment.

The manual is comprehensive and gives instructions for someone unfamiliar with a rotary table, a mounting diagram and a nice exploded picture of the table with parts numbers for spares. The table is priced at $725 which although quite expensive by my standards is still within the range of an average hobbyist. The controller has backlash elimination and can ramp up and down the speed for movement which is great for accurate positioning. 4 steps per revolution), degrees, job (manual), programmed and slave where it can be controlled by the output of a different CNC device with direction and step controls. The controls have 5 modes, division (e.g.

It can be used to drill holes in a circle, for milling curved objects, gear cutting, large diameter turning and even be combined with other Sherline CNC tools for more complex operations. The advantages of attaching a stepper motor and control box to your rotary table is that you don’t need to deal with the mathematics, plates and counting associated with a regular dividing head. Thanks to Robot Magazine I’ve found out about the Sherline CNC Rotary Indexer Part No.

0 kommentar(er)

0 kommentar(er)